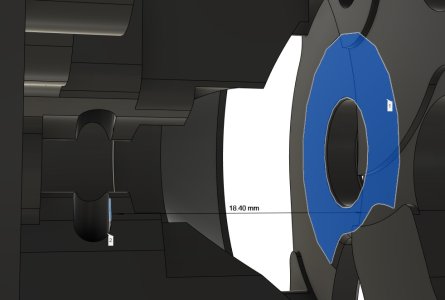

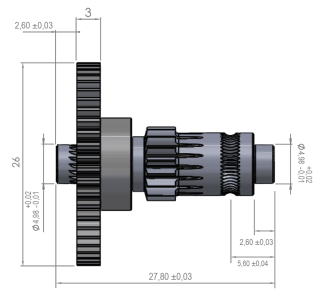

Hi All, I'm chasing some extruder issues on my new Trident build, and I thought I'd buy an original Bondtech gear set - IDGA seemed like a good way to eliminate any eccentricity in the drive. When I'm assembling CW2, it specifies 15.6mm offset from the drive gear to the centreline of the hobbed groove. Bondtech's drawing gives me 16.2mm (https://www.bondtech.se/product/oem-idga-set/), and it's enough that the Clockwork extruder doesn't snap together cleanly.

Is this even supported? Do I need to do something differently to get this to work? do I need to print a modified CW2 to get this working?

Is this even supported? Do I need to do something differently to get this to work? do I need to print a modified CW2 to get this working?