Pradit

Well-known member

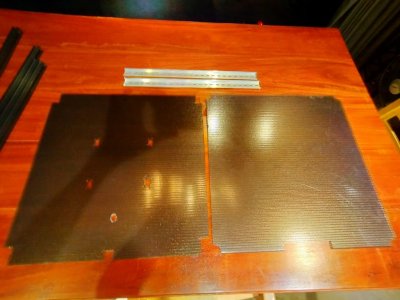

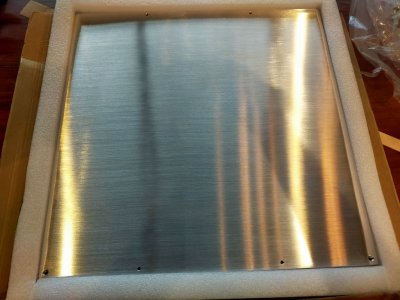

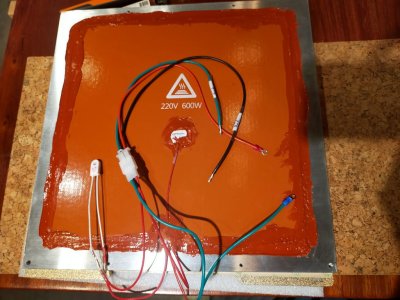

Finally I have the parts which I self source ready.

And I have a place to keep my build log.

I will come and keep update here once I finish managing the photo.

This web help you make your mind for the color.

# Plan for my build:

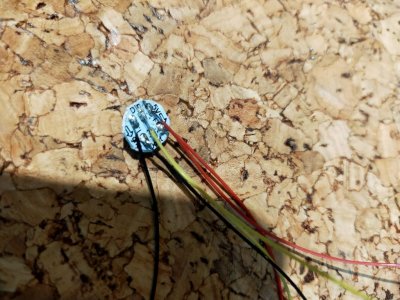

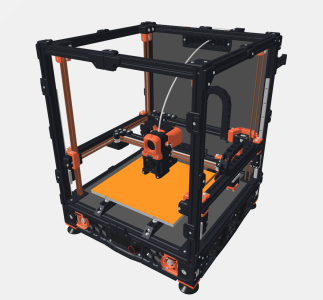

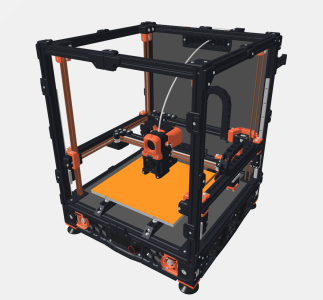

1. 350 x 350 build

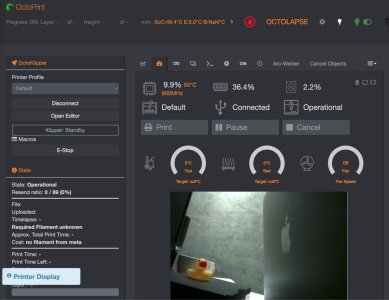

2. Octopus Pro 446 + TMC2209

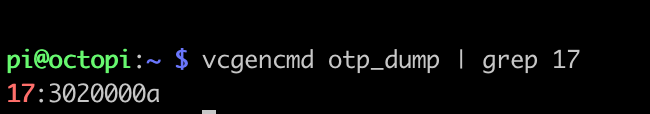

3. Raspberry Pi 3B +

4. EBB36 Canbus

5. PITFT5

6. PI cam

7. Smoke detection alarm

8. Rapido

9. Octoprint

10. Klipper

11. Octodash

12. Klicky

13. Filament runout Unklicky

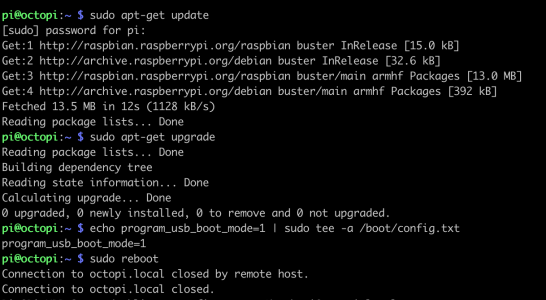

14. PurgeBucket & Nozzle brush

15. Sensorless Homing

16. Sexbolt

17. Nevermore filter and more filter

18. Some sort of removable panel and door with magnets.

19. Rolling Voron

20. Boot from SSD drive

21. LED LED LED and LED

22. Umbilical cord

23. Relocation chain

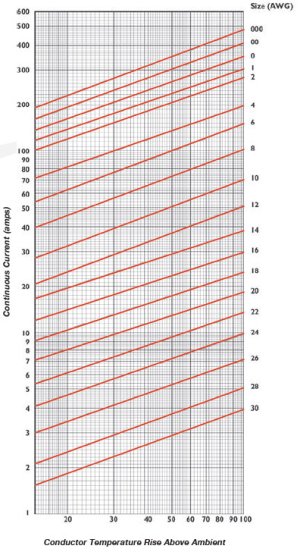

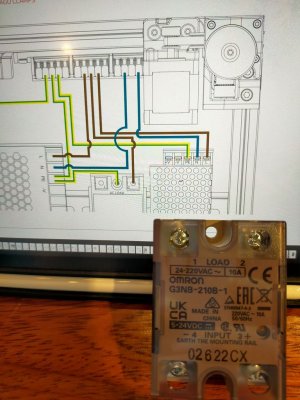

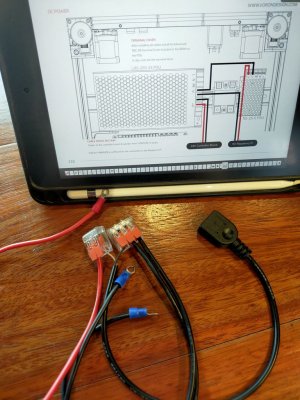

24. More on fire hazard prevent and protection

25. Remote monitor

Since I source every part by myself so it's a waiting game.

Then I started to order PIF from @Stephan (discord username).

He kindly helps me find a way to deliver to me with a cheaper fee from Germany. Thanks for that.

# PIF

Here are the bags of the main printer part for Voron 2.4 R2 Rapido.

All the parts from the bag.

Accent color is orange.

1st bag base color.

2nd bag base color.

3rd bag base color.

Below here you can look at the print quality from PIF.

And I have a place to keep my build log.

I will come and keep update here once I finish managing the photo.

This web help you make your mind for the color.

# Plan for my build:

1. 350 x 350 build

2. Octopus Pro 446 + TMC2209

3. Raspberry Pi 3B +

4. EBB36 Canbus

5. PITFT5

6. PI cam

7. Smoke detection alarm

8. Rapido

9. Octoprint

10. Klipper

11. Octodash

12. Klicky

13. Filament runout Unklicky

14. PurgeBucket & Nozzle brush

15. Sensorless Homing

16. Sexbolt

17. Nevermore filter and more filter

18. Some sort of removable panel and door with magnets.

19. Rolling Voron

20. Boot from SSD drive

21. LED LED LED and LED

22. Umbilical cord

23. Relocation chain

24. More on fire hazard prevent and protection

25. Remote monitor

Since I source every part by myself so it's a waiting game.

Then I started to order PIF from @Stephan (discord username).

He kindly helps me find a way to deliver to me with a cheaper fee from Germany. Thanks for that.

# PIF

Here are the bags of the main printer part for Voron 2.4 R2 Rapido.

All the parts from the bag.

Accent color is orange.

1st bag base color.

2nd bag base color.

3rd bag base color.

Below here you can look at the print quality from PIF.

Last edited: