Same story. I've ordered 4 v0.1s and two 2.4 350s from them. Shipping was under a week. voronkits.com was the same, but they are just another dropship reseller of formbot kits so...but they sell fully constructed vorons, though I don't know how well they operate. But you are guaranteed to get it shipped from the states from them, at least that's what they say and I have nothing to counter that statement.

Fysetc was the same, from their site not AE. And they did ship from China.

I'll order from their respective, actual, web sites from now on. They are quick and I don't have to deal with Mr. Ali, or Mr. Amzn.

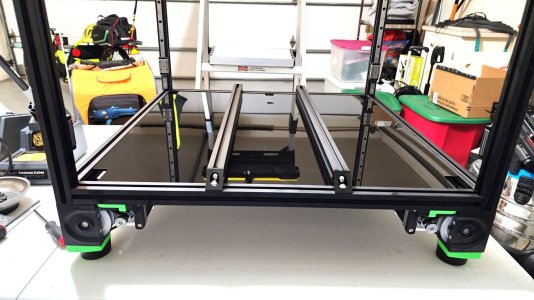

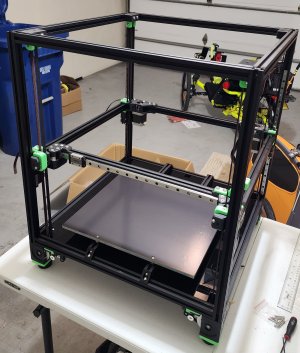

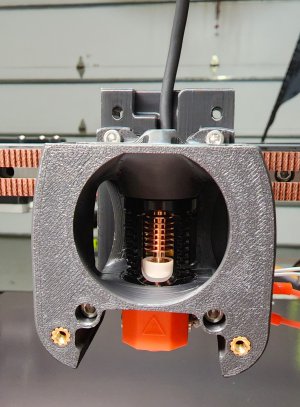

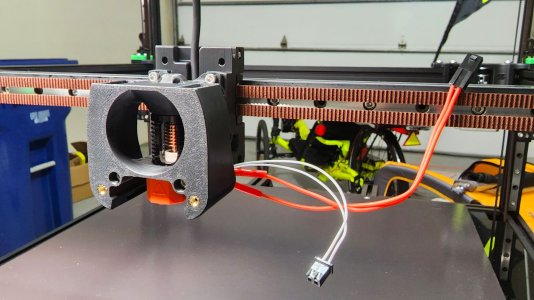

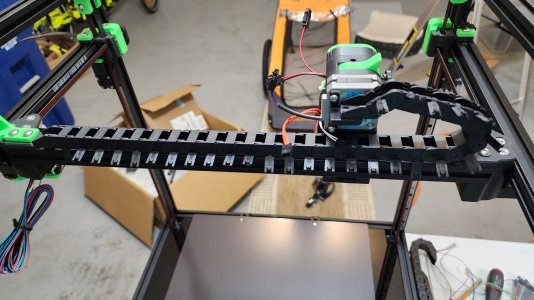

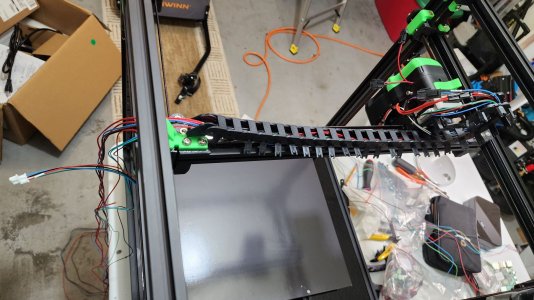

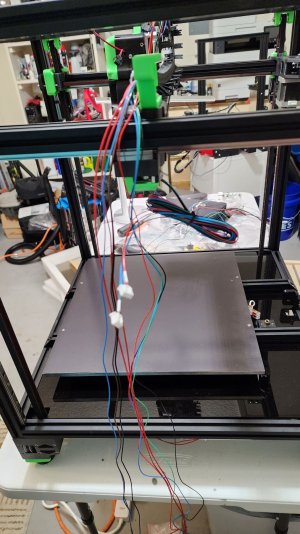

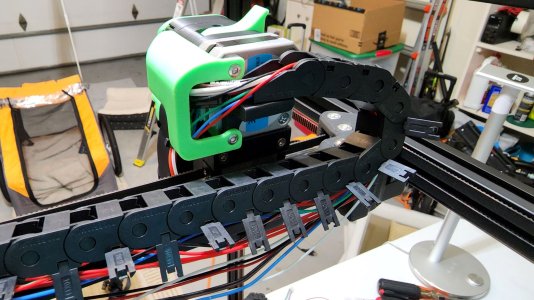

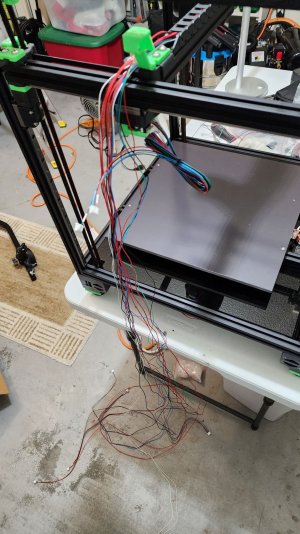

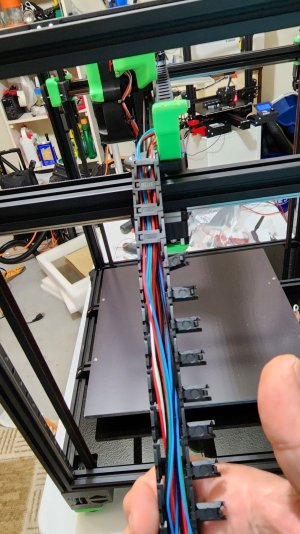

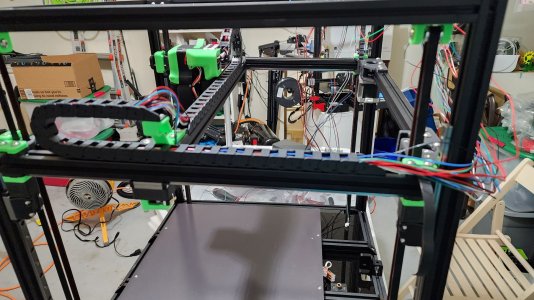

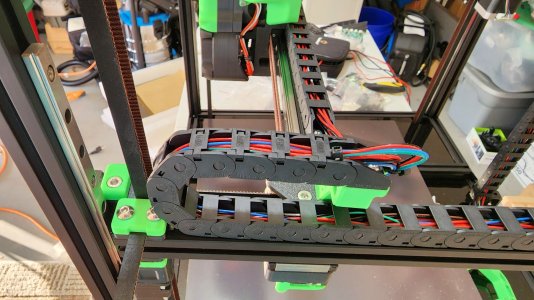

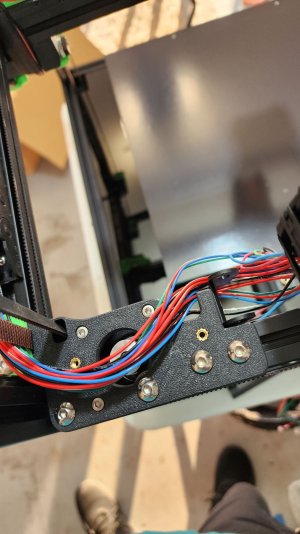

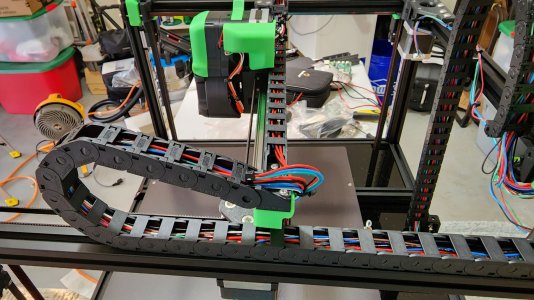

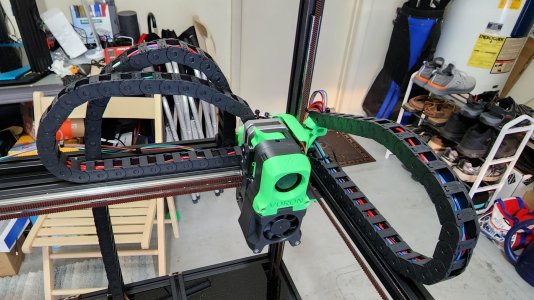

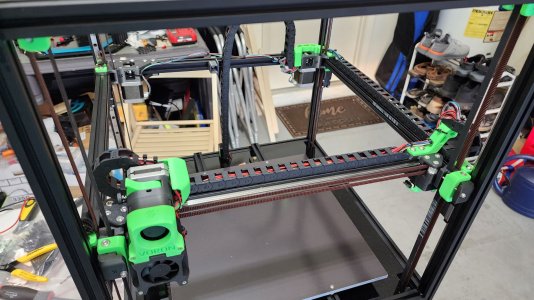

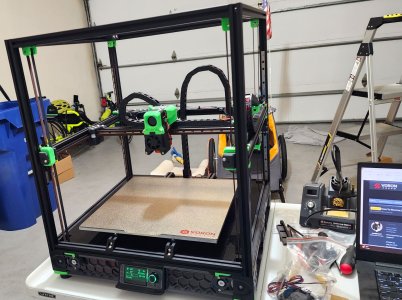

Liking the build

@LoadMaster7, exciting to get close to the end.

I might start some logs for my other vorons, but man I don't like taking side steps to just take pictures and edit it all.

forgot to add: the only real grip I have against the formbot kit is that the screws are not stainless. They are magnetic. Might not be much of an issue now, but we get humidity here, and all the different metals touching together...with more ferrous metal in there...might cause some concern. Or maybe not. I just know how different metals touching together isn't really ideal without some sort of anti-corrosion treatment.