VORON Design

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

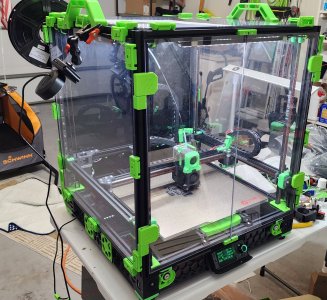

My First Voron 2.4 R2 Formbot 350 X 350 X 350mm - Dragon High Flow

- Thread starter LoadMaster7

- Start date

LoadMaster7

Well-known member

I switched over to Octoprint/Klipper. My primary reason, I have OctoEverywhere that allows me to control the printer no matter where I am as long as I have an internet connection. I can live stream my print jobs. It is a bit boring I guess, but still fun to play with. At least my wife calls it boring when I display a print job on our TV!

Updated Live Stream 01-06-23

Updated Live Stream 01-06-23

Last edited:

msaeger

Well-known member

It's good to hear that works. I was under the impression octoeverywhere didn't work with klipper.I switched over to Octoprint/Klipper. My primary reason, I have OctoEverywhere that allows me to control the printer no matter where I am as long as I have an internet connection. I can live stream my print jobs. It is a bit boring I guess, but still fun to play with. At least my wife calls it boring when I display a print job on our TV!

LIVE - Watch Me Make Things

Live stream your 3D printed creations to your friends or the world with a live webcam stream, real-time print stats, and more.octoeverywhere.com

LoadMaster7

Well-known member

Yeah, it works well. I'm not as much of a fan of Octoprint with Klipper. It has its good points, large selection of add-ons, but the built in editor leaves a lot to desire, or maybe I am missing something. I can't find anyway to search a word with the editor.It's good to hear that works. I was under the impression octoeverywhere didn't work with klipper.

LoadMaster7

Well-known member

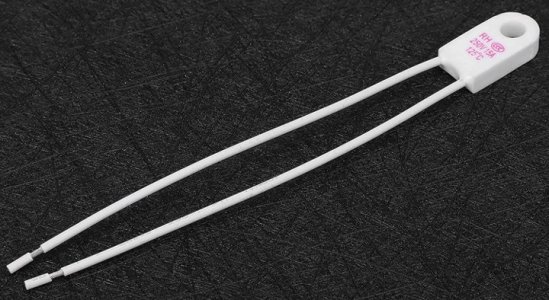

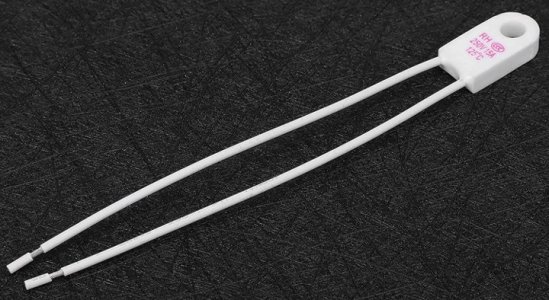

Interesting. I am printing PLA parts at 60° C bedplate temp and I had a a shutdown. Not for overtemp, but not responding as expected. The bedplate's thermo fuse opened. I had a spare and that corrected the issue. I don't understand why the original one opened. I placed an order right away as I have no more spares.

Anyone else have their bedplate fuse fail? I'm wondering if I could of had a bad one or if there is something else going on. Time will tell.

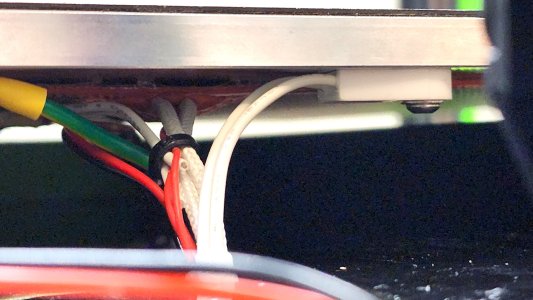

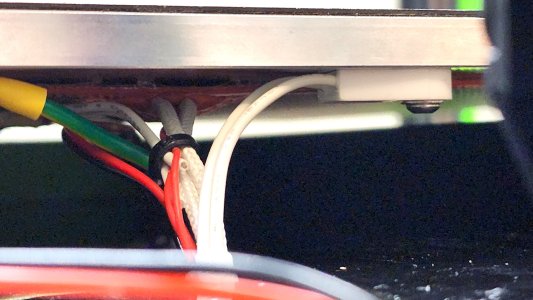

This shows the new fuse mounted to the original location. My first fuse was RTV glued to the heating pad. Not sure of the cause, but this fuse failed. Since installing new fuse to the bedplate I have had no more issues.

Anyone else have their bedplate fuse fail? I'm wondering if I could of had a bad one or if there is something else going on. Time will tell.

This shows the new fuse mounted to the original location. My first fuse was RTV glued to the heating pad. Not sure of the cause, but this fuse failed. Since installing new fuse to the bedplate I have had no more issues.

Last edited:

msaeger

Well-known member

You would think that you would get the software error before the fuse would blow. Is there something that needs to configured differently maybe?Interesting. I am printing PLA parts at 60° C bedplate temp and I had a a shutdown. Not for overtemp, but not responding as expected. The bedplate's thermo fuse opened. I had a spare and that corrected the issue. I don't understand why the original one opened. I placed an order right away as I have no more spares.

Anyone else have their bedplate fuse fail? I'm wondering if I could of had a bad one or if there is something else going on. Time will tell.

View attachment 1263

WhiteWulfe

Well-known member

I generally just purchase from a verified source. Sparta3D, West3D, vendors who carry the Nevermore branded stuff...It warns to only use acid-free carbon. I'm not sure how you tell if the carbon is acid-free. None of the source I've looked at say.

LoadMaster7

Well-known member

Yeah, I agree that I expected software error first, but that is not what happened. I have a guess, but nothing for sure. I recently upped the bed max from 60% to 70%. During my build, I took the suggestion to rtv the fuse to the bottom of the heating pad. This was suggested as a safety in case the heat pad came loose from the plate. Thinking back on it, that may have been a bad suggestion. I have never seen a heat pad separate from where it is attached. For the replacement fuse, it is installed with a screw to the original bedplate location. So far, no issue.You would think that you would get the software error before the fuse would blow. Is there something that needs to configured differently maybe?

LoadMaster7

Well-known member

LoadMaster7

Well-known member

I'm still learning, everyday with this Voron 2.4 R2. Man, what a great printer!!! I have found, (I'm sure others know this) if the Quad Gantry Level takes more than two passes, something is loose. I have had belts, and gantry screws that have loosened. It might be due to thermo cycling now that that the printer is fully enclosed. I have once again, gone over all of the belt and screws to make sure they are where they should be. The clock starts today to see how long I can use the printer before needing to adjust them.

I have added a few things, including a 24 to 12 volt power buck to supply my printer chamber LED's, a manual switch and a USB power outlet with voltage readout meter. I know they are not needed, but they were free, so why not?

I have also installed a purge bucket and brush. This is up and working well.

I have added a few things, including a 24 to 12 volt power buck to supply my printer chamber LED's, a manual switch and a USB power outlet with voltage readout meter. I know they are not needed, but they were free, so why not?

I have also installed a purge bucket and brush. This is up and working well.

Attachments

LoadMaster7

Well-known member

I had a strange thing happen with my Afterburner. I changed out the filament in my normal fashion, using the display panel. The filament drive gear popped out from the lever and the filament wouldn't feed. I wasn't a big deal. I pulled it out, cleaned and greased it. Reinstalled it, and all is working as it should. I don't understand how it popped out from its mount.

LoadMaster7

Well-known member

I have been enjoying my printer and trying different filaments and adjusting things closer to perfect with each use. I have most of the parts for converting to Stealthburner. This might also include adding CAN. I am in no hurry mainly because the printer is working so well as is.

I printed my first Benchy boat today using Hatchbox translucent yellow ABS filament. I am really liking this filament. Prints nice.

I printed my first Benchy boat today using Hatchbox translucent yellow ABS filament. I am really liking this filament. Prints nice.

LoadMaster7

Well-known member

I can understand how it could be a challenge to see. I try and start with a known good profile and run a few test, like printing a benchy or a cube. If these come out well, I save the profile with all of the details for the given filament and how I used it. I sometimes mark the reel of filament with a profile names, if it is a filament I don't use regularly.Benchy looks nice. I personally do not like transparent filament. I was trying to print some transparent blue the last few days and I can't see if the first layer is good, but maybe its just my old eyes.

LoadMaster7

Well-known member

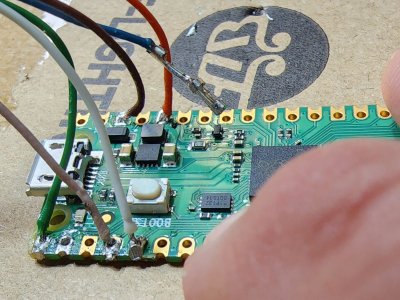

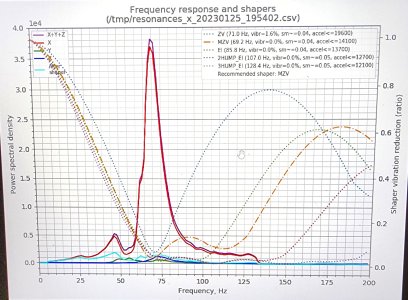

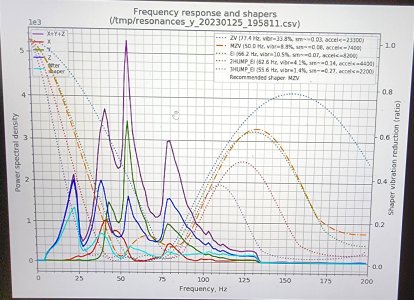

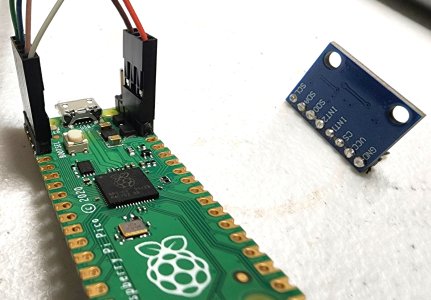

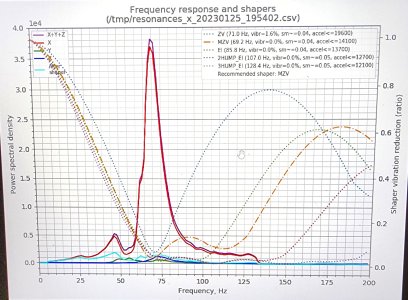

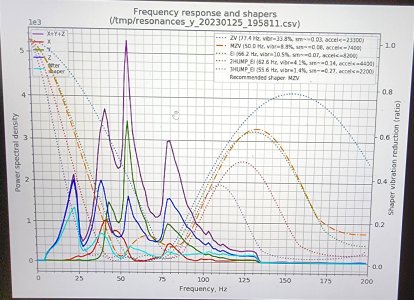

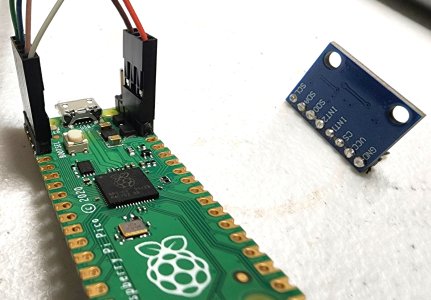

Wow, my trip to input shaping was a challenge, but I got it done! I ended up going with a Raspberry Pi Pico with a ADXL345 attached. It took me a number of tries to make it work. Following a number of videos and other online help, I found out a number of things I didn't know. Like the differences in cat Ethernet cables. I had a number of different cables that I tried to use as connecting wire between the Pi Pico and the ADXL345. The first cable, to my surprise was solid wire, so I skipped using it. The second one had individual strands, so I thought it would be a good choice, only to find out the wire refused to solider. I have never experienced this before. So, I ended up crimping connectors to make all of the connections, and this worked fine.

What a difference in performance! This was well worth the effort.

What a difference in performance! This was well worth the effort.

LoadMaster7

Well-known member

LoadMaster7

Well-known member

I use this mostly as a learning platform. These little micro processorsLooks like you built your machine well and have it on a nice stable platform.

LoadMaster7

Well-known member

This is the values from my Input Shaper process.

#*# <---------------------- SAVE_CONFIG ---------------------->

#*# DO NOT EDIT THIS BLOCK OR BELOW. The contents are auto-generated.

#*#

#*# [stepper_z]

#*# position_endstop = 1.533

#*#

#*# [extruder]

#*# control = pid

#*# pid_kp = 33.810

#*# pid_ki = 2.450

#*# pid_kd = 116.644

#*#

#*# [input_shaper]

#*# shaper_type_x = mzv

#*# shaper_freq_x = 72.2

#*# shaper_type_y = 2hump_ei

#*# shaper_freq_y = 64.0

LoadMaster7

Well-known member

Lesson number 100. After running input shaper, check all screws and bolts! My printer stopped running the quad gantry level. I had changed nothing that should have caused this. Checking things over, I found a number of screws, including the inductive pickup mounting screws loose. I found it strange that the pickup had moved up enough that it wouldn't trigger and would cause an error message, pointing that the toolhead traveled more than allowed without trigger. All of this made me look everything over. Moved the inductive pickup down 3mm, tightened loose screws and the printer world is back to normal.

So, now I am wondering if I should rerun the input shaper process seeing I had to tighten things back up? If I rerun it, will it all become loose again? So many questions!!

So, now I am wondering if I should rerun the input shaper process seeing I had to tighten things back up? If I rerun it, will it all become loose again? So many questions!!

Similar threads

- Replies

- 26

- Views

- 1K

- Replies

- 7

- Views

- 1K