Why build a 3D printer?

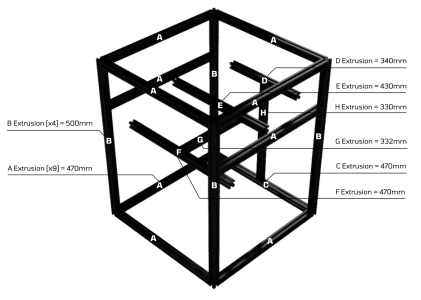

I started on the 3D printer build journey when I was trying to create some printed parts for a custom rack. It took me a few weeks to learn enough of Autodesk Fusion 360 to create the parts. When I tried to print the parts from an online service, the quote for cost of printing was enough to fund an entry level 3D printer. That set me thinking that maybe I should buy a 3D printer. To cut the story short, somewhere along my search for selecting a 3D printer, I pivoted to building an open source Voron Trident 350. My main motivation is learning something new.

Why VT350 and not a smaller size?

Because, my custom part is large enough to warrant a VT350.

Why self source and not use a kit?

I believe that the learning experience self sourcing provides is much richer than using a kit. It allows you to cherry pick printer components. It’s a little cheaper. I initially thought of doing a stock build as people have been advising. But, I realised that I would rather have some of the mods to start with rather than retrofitting them later. The guiding principle for making choices and picking some of the components was to use things that are slightly ahead in the technology curve.

Here goes my first post.

I started on the 3D printer build journey when I was trying to create some printed parts for a custom rack. It took me a few weeks to learn enough of Autodesk Fusion 360 to create the parts. When I tried to print the parts from an online service, the quote for cost of printing was enough to fund an entry level 3D printer. That set me thinking that maybe I should buy a 3D printer. To cut the story short, somewhere along my search for selecting a 3D printer, I pivoted to building an open source Voron Trident 350. My main motivation is learning something new.

Why VT350 and not a smaller size?

Because, my custom part is large enough to warrant a VT350.

Why self source and not use a kit?

I believe that the learning experience self sourcing provides is much richer than using a kit. It allows you to cherry pick printer components. It’s a little cheaper. I initially thought of doing a stock build as people have been advising. But, I realised that I would rather have some of the mods to start with rather than retrofitting them later. The guiding principle for making choices and picking some of the components was to use things that are slightly ahead in the technology curve.

Here goes my first post.