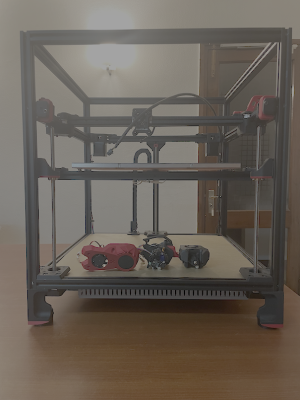

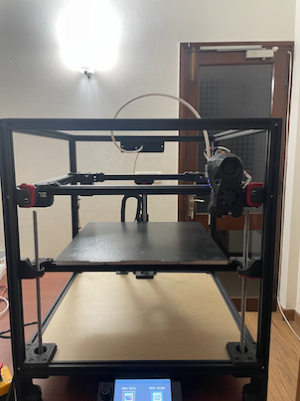

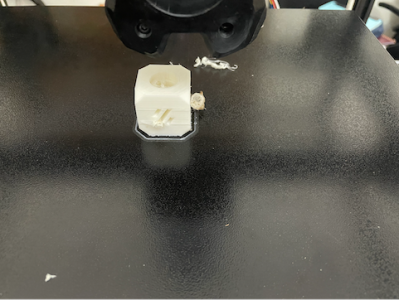

I’ve parked the toolhead assembly for some time due to the struggles with the H2 V2X extruder. Dc3d was kind enough to reprint the entire lot of printed parts for H2 V2X using ASA. They seemed to be holding up better than the ABS ones until the extruder mount spontaneously snapped. May be I’m doing something wrong. Probably tightening too much. This time around I was more careful. I’m not very confident that the H2 V2X extruder assembly is not going to come apart mid print. I’ve called off the toolhead build using H2 V2X.

Page 23 of the StealthBurner Assembly Manual has this joke -

I’ve already done that two times!

I’m considering four toolhead options

(1) Fallback to stock SB + ClockWork 2 - I’ve sourced some cheap generic gears to finish the CW2. The thought of crimping and running loads of wires from MCU to the toolhead is not looking very appealing.

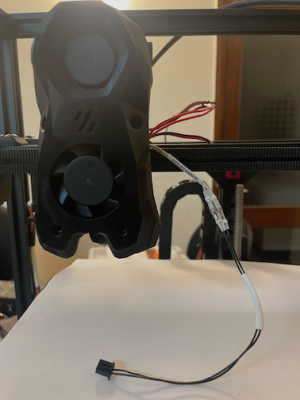

(2) SB + ClockWork 2 + EBB - I’ve rigged up an umbilical by wrapping a piano wire and the 4 core wire from BTT CAN Cable in a heat shrink tube.

(3) SB + Orbiter 2 + EBB - I sourced the Orbiter 2.0. The extruder mount looked straight forward in theory. I tried it but it did not fit properly.

(4) Xol + Orbiter 2 + EBB - the Delta fans mentioned in the Xol BOM are still not readily available here. Plus I’d have to carry out mods to the Z spacers and the front idlers.

I’m inclined towards (2) as a now. Not having a working 3D printer at my disposal limits the choices.

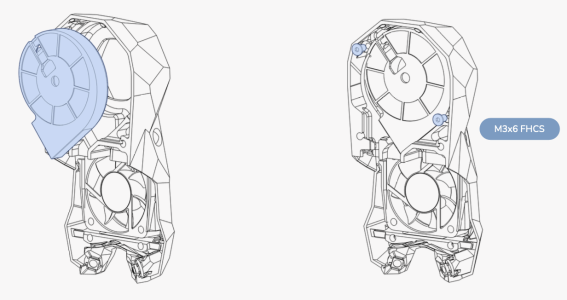

Page 23 of the StealthBurner Assembly Manual has this joke -

DON’T OVERTIGHTEN

Tighten until the plastic bends and cracks. Back up 2 turns, discard parts, reprint and try again.

I’ve already done that two times!

I’m considering four toolhead options

(1) Fallback to stock SB + ClockWork 2 - I’ve sourced some cheap generic gears to finish the CW2. The thought of crimping and running loads of wires from MCU to the toolhead is not looking very appealing.

(2) SB + ClockWork 2 + EBB - I’ve rigged up an umbilical by wrapping a piano wire and the 4 core wire from BTT CAN Cable in a heat shrink tube.

(3) SB + Orbiter 2 + EBB - I sourced the Orbiter 2.0. The extruder mount looked straight forward in theory. I tried it but it did not fit properly.

(4) Xol + Orbiter 2 + EBB - the Delta fans mentioned in the Xol BOM are still not readily available here. Plus I’d have to carry out mods to the Z spacers and the front idlers.

I’m inclined towards (2) as a now. Not having a working 3D printer at my disposal limits the choices.