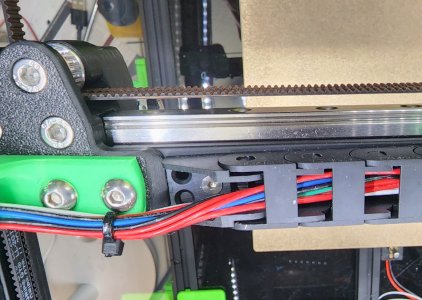

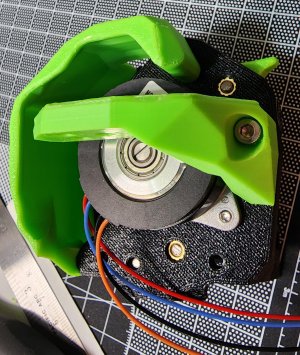

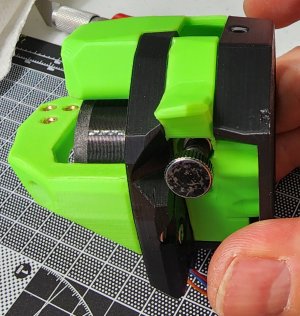

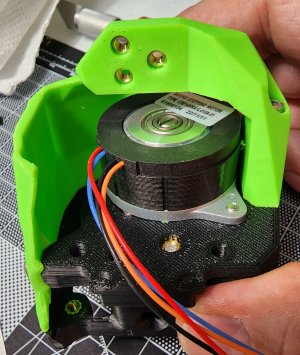

YES, I say put it through the stress, this way you can sort out the errors of issues now while you are calibrating instead of half way thought a 4 year print.Lesson number 100. After running input shaper, check all screws and bolts! My printer stopped running the quad gantry level. I had changed nothing that should have caused this. Checking things over, I found a number of screws, including the inductive pickup mounting screws loose. I found it strange that the pickup had moved up enough that it wouldn't trigger and would cause an error message, pointing that the toolhead traveled more than allowed without trigger. All of this made me look everything over. Moved the inductive pickup down 3mm, tightened loose screws and the printer world is back to normal.

So, now I am wondering if I should rerun the input shaper process seeing I had to tighten things back up? If I rerun it, will it all become loose again? So many questions!!

Post the .PNG file from Input shaper, its easier for me to spot issues like loose bolt looking at the graph. You can tell a lot of things by the graphs.