And so it starts ,

this should be frustrating, time consuming and fairly expensive but totally worth it when it finally goes brrrr!

Due to long lead times for the frame and a life I haven’t finalized many things at this point in regards to hardware choices and setup, but now that the box of aluminum sticks landed I guess it’s time to commit before I change my mind.

Here’s what it is, so far…

Doomcube/EZbake Trident

Frame - DLLPDF

Color - Illusion Chartreuse

Build area - 300x300x300

100mm extra height for umbilical and stuff.

this should be frustrating, time consuming and fairly expensive but totally worth it when it finally goes brrrr!

Due to long lead times for the frame and a life I haven’t finalized many things at this point in regards to hardware choices and setup, but now that the box of aluminum sticks landed I guess it’s time to commit before I change my mind.

Here’s what it is, so far…

Doomcube/EZbake Trident

Frame - DLLPDF

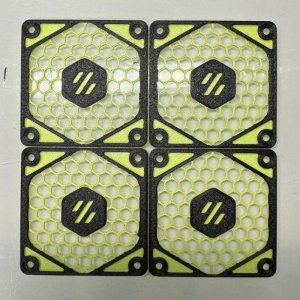

Color - Illusion Chartreuse

Build area - 300x300x300

100mm extra height for umbilical and stuff.

Last edited: