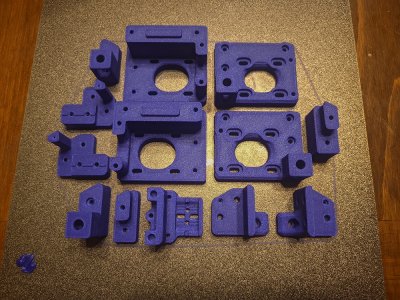

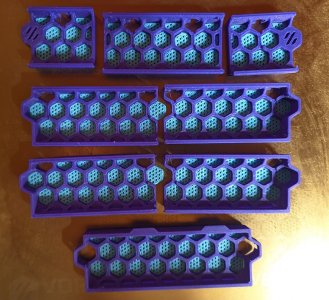

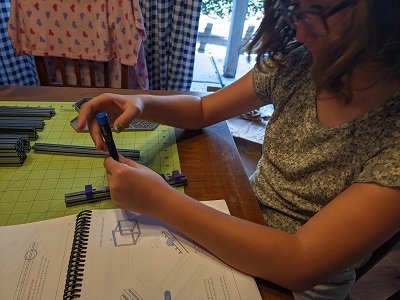

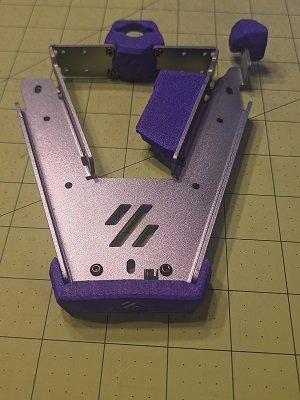

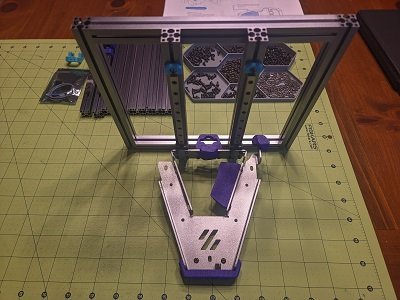

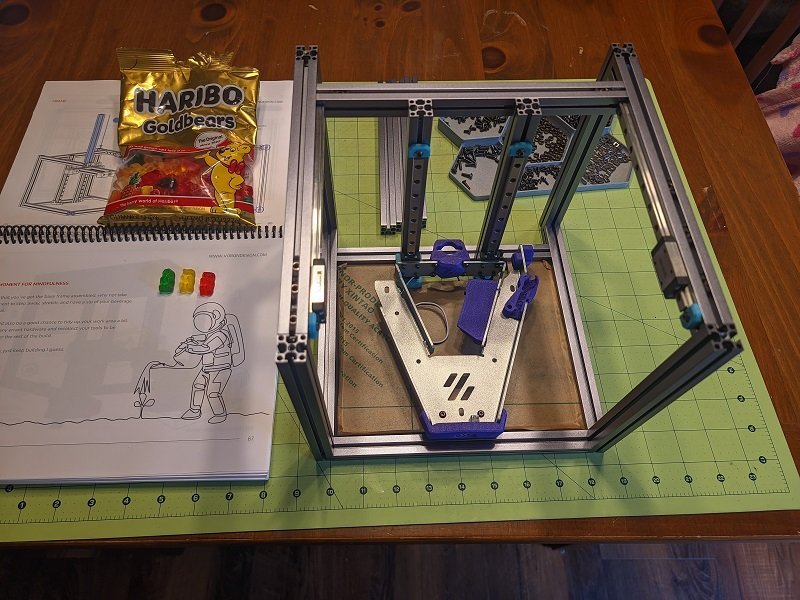

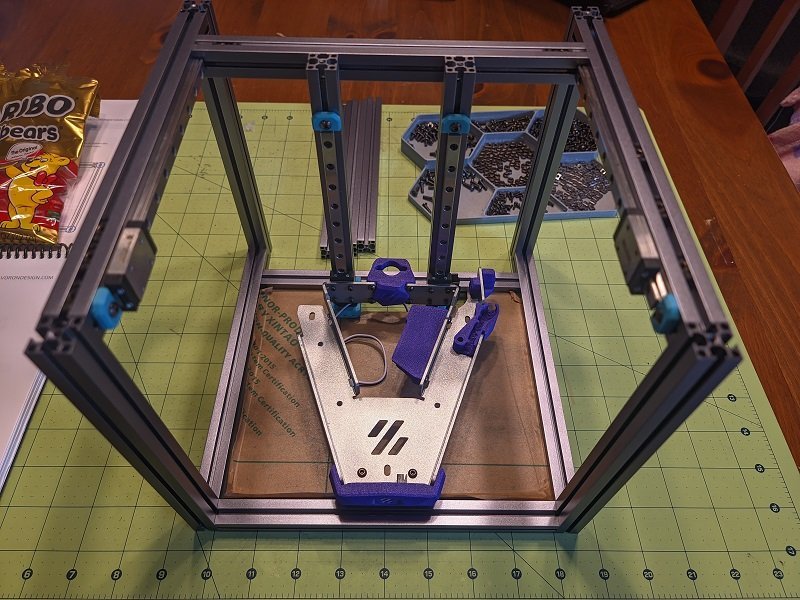

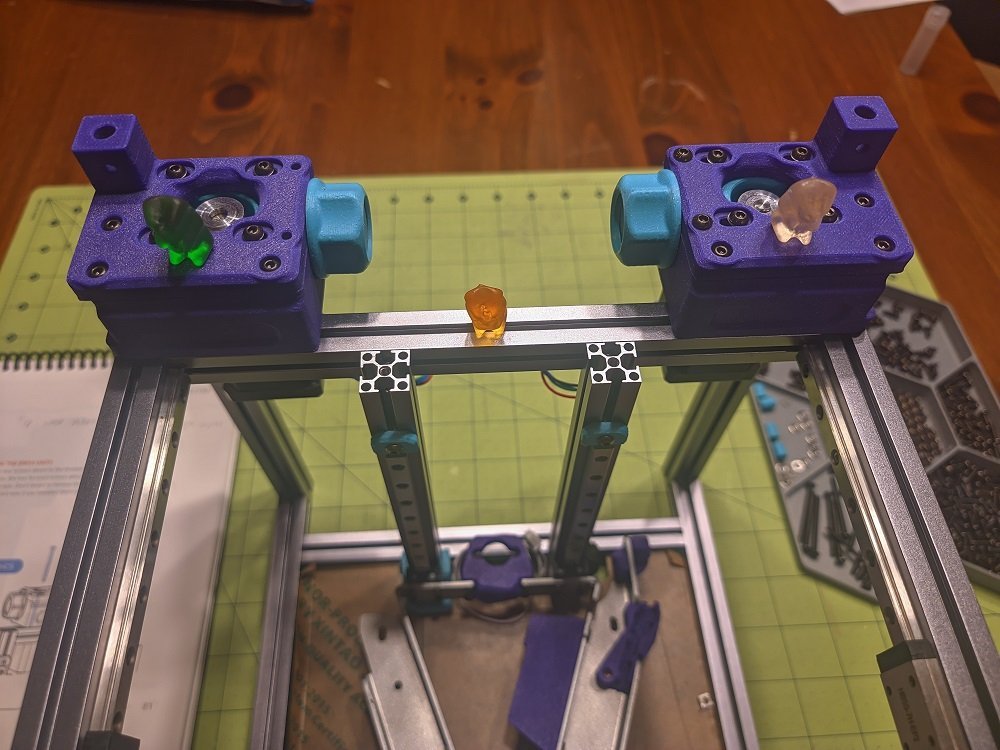

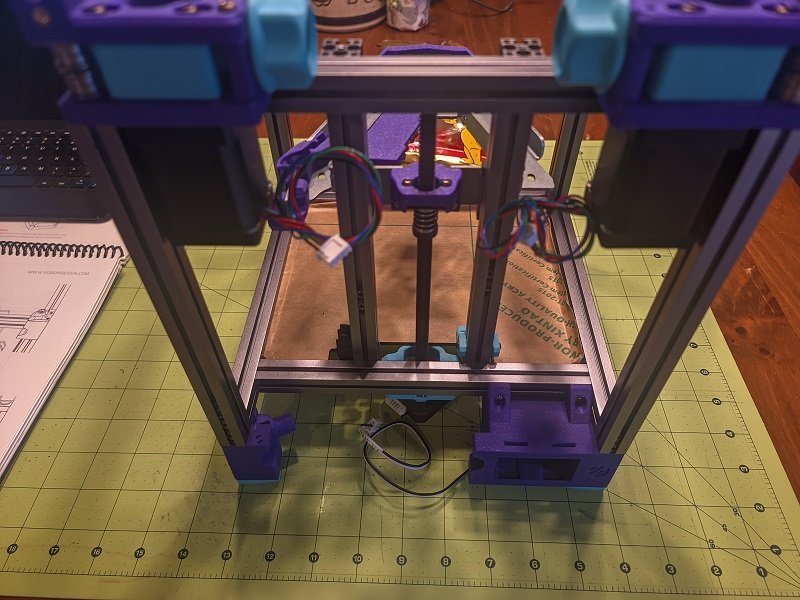

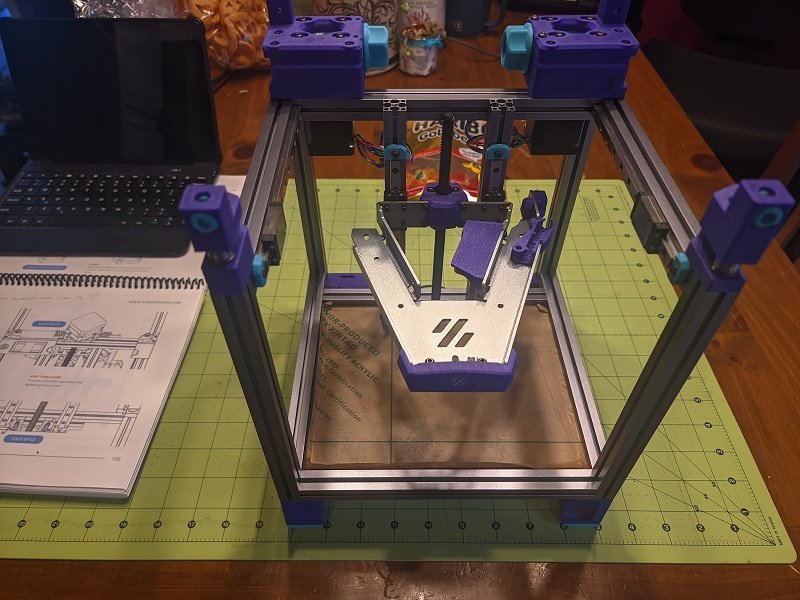

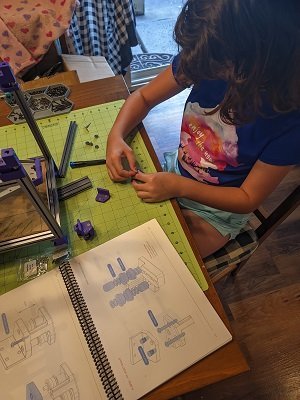

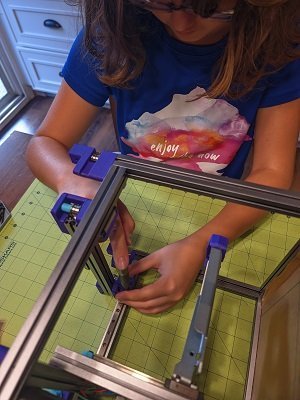

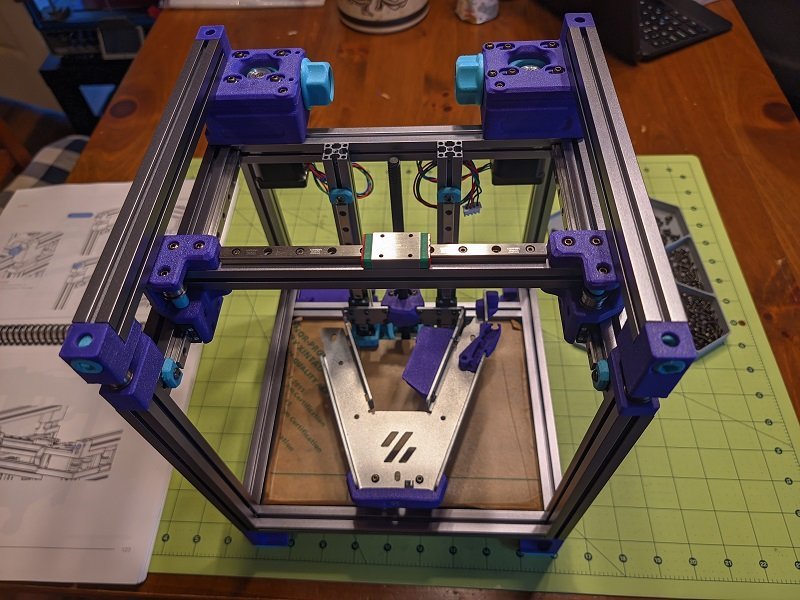

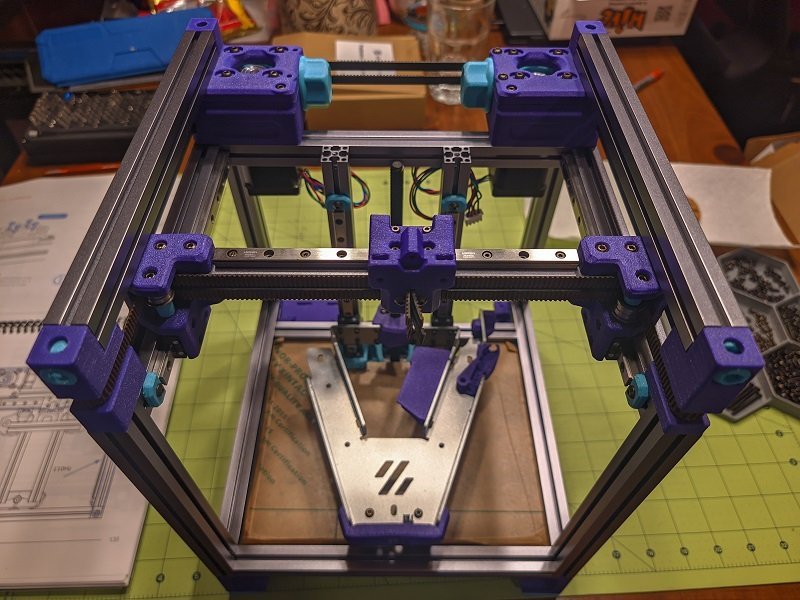

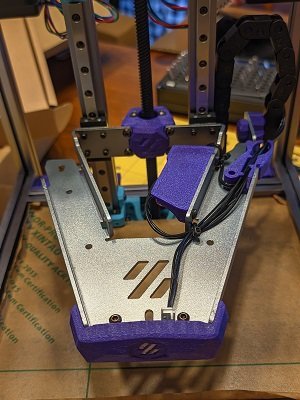

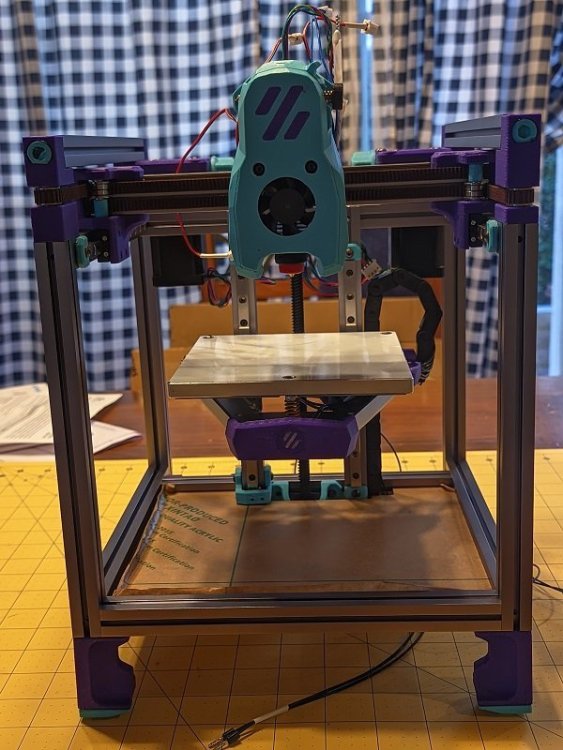

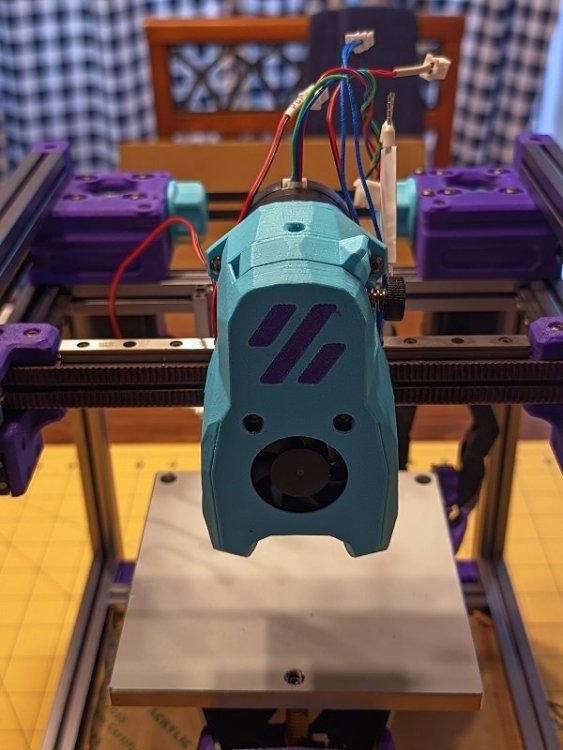

I'll get an early start on this while waiting on the kit to arrive. I've been plotting a V0 build for a while & the Voron holiday giveaway gave a kick with me receiving a V0 printed manual; now Hector throwing a coupon and digging up a space gray kit in stock while on a Nero stream gave a final push. So I couldn't say no, right? I was planning a Rook first as a father-daughter project this summer, but the V0 jumped the line (much to my bank account's pain). I'm planning Fusion Geomagnetic Mauve as the primary color, and Polymaker Galaxy Teal as the accent; should look good.

My first challenge is the Pi. I don't have a Zero 2W, and they are unobtanium unless you want to spend >$100 (on a $15 board? Yeah, no). I have a couple of 3Bs hoarded so I can get it up and running, but it looks like I'll have to steal the mount file from my Trident. I can get a Zero 2 locally, but I don't think that has quite the horsepower to run it, correct? I'd like to eventually run a webcam and of course be able to do input shaping. I don't think the LDO Picobilical PCB would help there, right?

My first challenge is the Pi. I don't have a Zero 2W, and they are unobtanium unless you want to spend >$100 (on a $15 board? Yeah, no). I have a couple of 3Bs hoarded so I can get it up and running, but it looks like I'll have to steal the mount file from my Trident. I can get a Zero 2 locally, but I don't think that has quite the horsepower to run it, correct? I'd like to eventually run a webcam and of course be able to do input shaping. I don't think the LDO Picobilical PCB would help there, right?