Background:

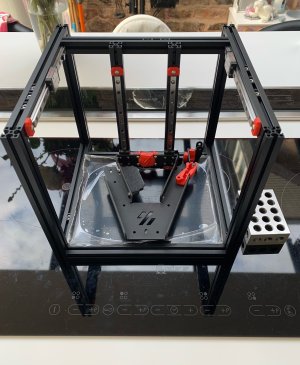

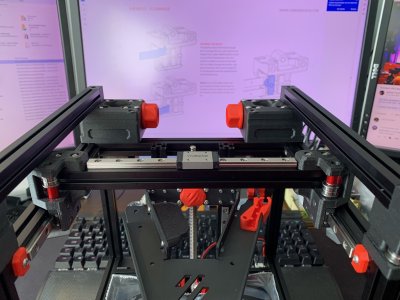

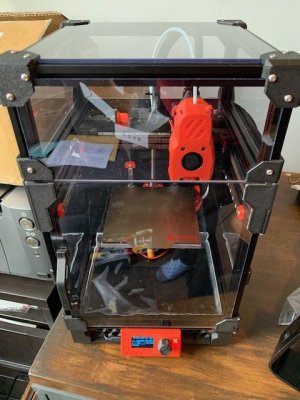

I was one of the many Kickstarters who bought the Creality CR-6 SE in 2020 as their first 3D printer. However, I am probably one of the rarer individuals who only unboxed and started printing with it 2 months ago. After that was upgraded with Octoprint, modded firmware, PEI, dual gear extruder, a new toolhead and various other quality of life improvements, the time came to move this newhobby obsession to the next level. £430 (£70 import tax) lighter, and two boxes arrived to the UK from China from Formbot within a week via Fedex. I am hoping to use the experiences here for a Voron v2.4r2 350mm in a few months time, as well as use this for v2.4's functional parts in ABS.

The Build:

I have been closely following @Perkeo 's build, trying to absorb everything.

Dmason's V0.1 blog has also been useful: https://3dpandme.com/category/printer-builds/v0-1/

Ballistic Tech has a vlog on this kit here: https://www.youtube.com/playlist?list=PLwWNdxHVFVf1DbI2nGngUB0O9TWeXn2Sx

I am pretty happy with electronics, linux command line and mechanicals. Although had to purchase some crimpers and a couple of 123 blocks for the build. Additional things not included in the Formbot kit: Lithium EP2 grease, Isopropanol Alcohol 99.9%, threadlocker, various connectors (Wagos, XT60, JST).

Voron Discord Profile: Lik#5169

I was one of the many Kickstarters who bought the Creality CR-6 SE in 2020 as their first 3D printer. However, I am probably one of the rarer individuals who only unboxed and started printing with it 2 months ago. After that was upgraded with Octoprint, modded firmware, PEI, dual gear extruder, a new toolhead and various other quality of life improvements, the time came to move this new

The Build:

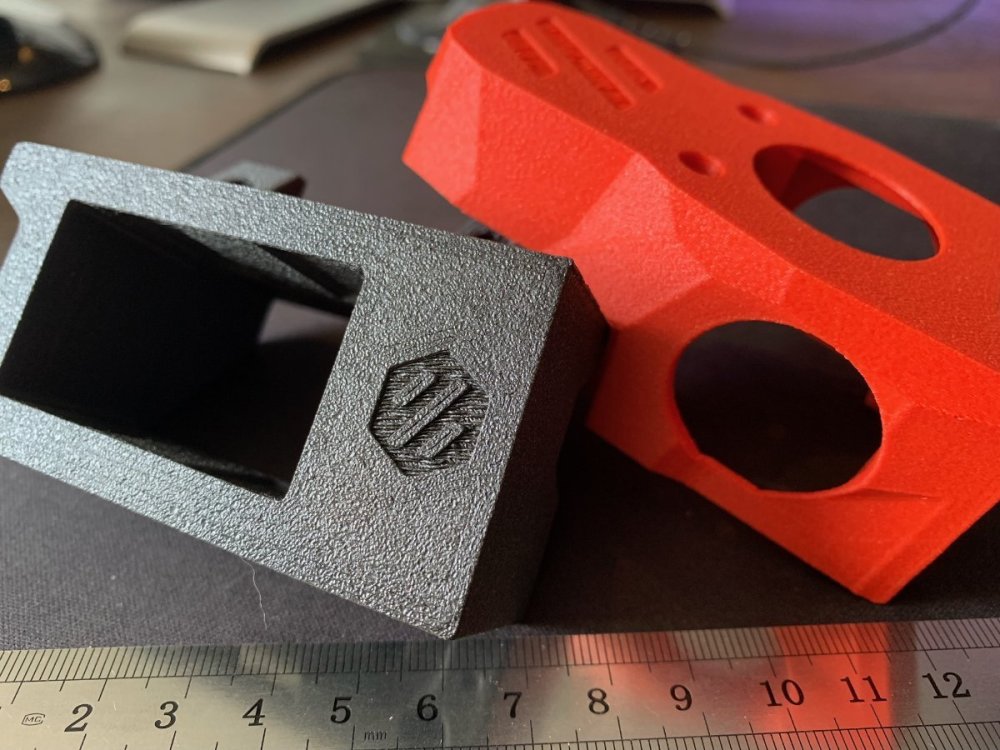

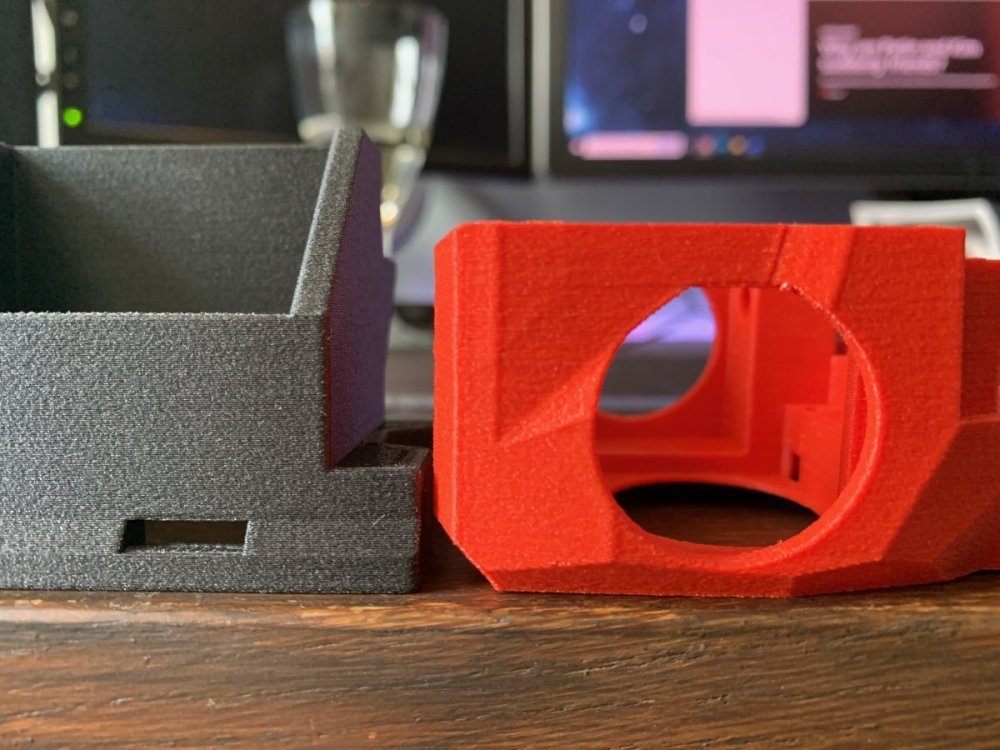

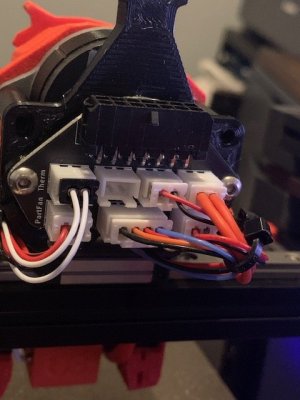

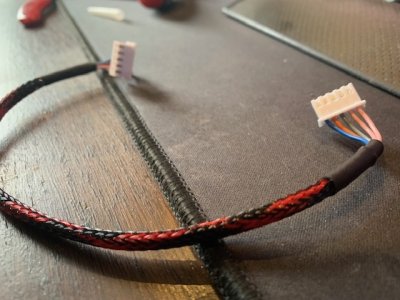

- Formbot V0.2r1 Kit with all ABS parts - includes Kirigami, Umbilical PCB

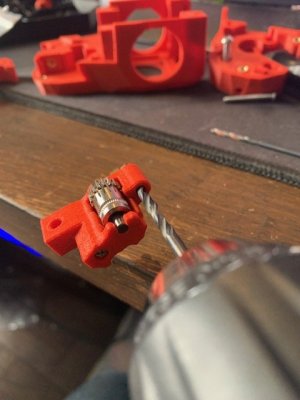

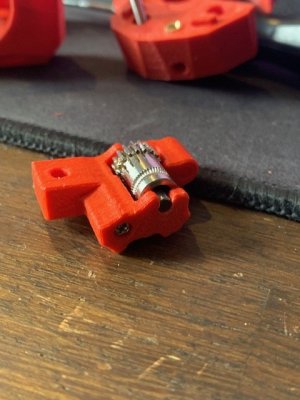

- Phaetus Dragon SF hotend with 0.4mm nozzle

- Siboor Steel Kirigami Bed

- BTT SKR Pico

- BTT Pi v1.2

- BTT TFT35 SPI (for BTT PI)

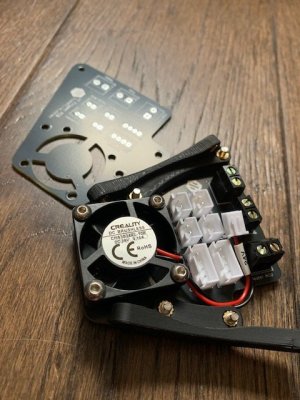

- Klipper Expander - for extra fans, Neopixels and thermistors (https://github.com/VoronDesign/Voron-Hardware/tree/master/Klipper_Expander)

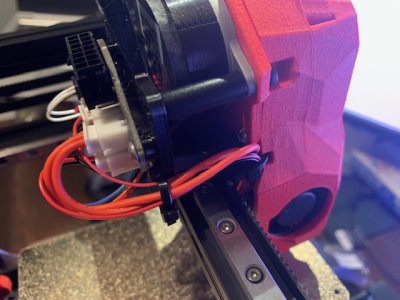

- MFNano (https://github.com/MapleLeafMakers/MFNano)

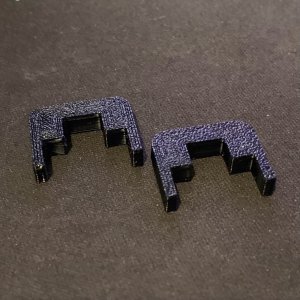

- V0 No-Drop Nuts (https://github.com/VoronDesign/VoronUsers/tree/master/printer_mods/zruncho/V0_No_Drop_Nuts)

- Foldable spool mount (https://www.printables.com/model/542953-locking-foldable-spool-holder-for-voron-v02-0-v0-0)

- DIN mounted electronics (https://www.printables.com/model/586977-voron-v02-electronics-din-rail-bracket)

- Modesty Mesh (https://www.printables.com/model/407822-voron-v0-modesty-mesh)

- Cable duct (https://github.com/VoronDesign/VoronUsers/tree/master/printer_mods/ryandam/Cable_management_duct)

- Klipper Expander duct (https://www.printables.com/model/317519-voron-v01-v02-klipper-expander-cable-duct)

- V0 Stealth Handles (https://github.com/MapleLeafMakers/V0_Stealth_Handles)

- Kirigami PCB (https://github.com/livinhack/Kirigami-PCB)

- Kirigami Neopixel (https://github.com/MapleLeafMakers/Stealth_Bed_Front)

- Lighting - Rainbow On A Matchstick (https://github.com/VoronDesign/Voron-Hardware/tree/master/Daylight)

- Chamber thermistor mount (https://github.com/MapleLeafMakers/V0_Chamber_Thermistor_Mount)

- ZeroClick probe (https://github.com/zruncho3d/ZeroClick)

- PanzerObserver camera mount (https://github.com/Slidr666/VoronUs...14d0a496/printer_mods/Slidr/PanzerObserver2.4)

- Possibly - DragonBurner V8 toolhead and CAN bus (BTT) in future, depending on tinkering motivation!

I have been closely following @Perkeo 's build, trying to absorb everything.

Dmason's V0.1 blog has also been useful: https://3dpandme.com/category/printer-builds/v0-1/

Ballistic Tech has a vlog on this kit here: https://www.youtube.com/playlist?list=PLwWNdxHVFVf1DbI2nGngUB0O9TWeXn2Sx

I am pretty happy with electronics, linux command line and mechanicals. Although had to purchase some crimpers and a couple of 123 blocks for the build. Additional things not included in the Formbot kit: Lithium EP2 grease, Isopropanol Alcohol 99.9%, threadlocker, various connectors (Wagos, XT60, JST).

Voron Discord Profile: Lik#5169

Last edited: