Cena

Active member

* Yet Another Clueless Noob

I bought this kit back in August, and I’m just now getting around to building it.

Why? I don’t have a great answer - I wanted a 3D printer, stumbled across Voron and RatRig, and, being the kind of person who is an unrepentant lover of maximalism, complexity, and learning from first principles, fell in love with the idea of building one of these things. I ended up going with Voron because at the time, I couldn’t find as complete a kit for RatRig, and the community seemed smaller.

The type of clueless noob I am: very little prior electronics knowledge, zero 3D printing experience or knowledge. However, I still want to make things as complicated as possible, so have spent an inordinate amount of time since August researching mods, CAN, TAP, Beacon, etc. I’ve finally convinced myself to follow the wisdom of others in building basically stock to start. That said:

Mods:

- clicky clack door

- Orbiter 2 runout sensor

- Knowmi (cuz it seems fun)

-Nitehawk

On the fence about, but it’s not too late:

- TAP vs Beacon

- inverted electronics

Note to self: NO (for now).

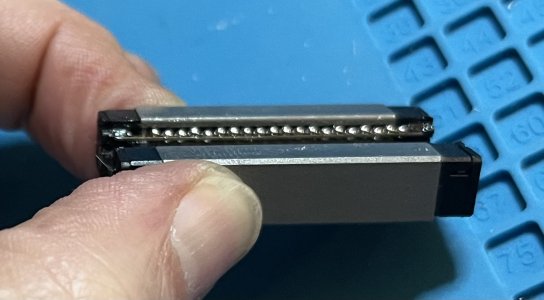

Anyway, I just started putting the frame together. @jonhi has a wonderful build log here that reminded me that LDO has its own build notes for its kits, so I took a look and found the very first note about installing the T-nuts first. Of course.

Actually, the T-nuts went into the completed frame just fine, thankfully .

However, now I’m at a hard stop because I just realized…..I bought printed parts for the wrong damn printer!!! After endless rooting around for the z-axis assembly and cussing out the hapless PIF-er, I finally looked at my actual order and the parts are for a V0.2. Did I mention clueless anywhere?

I’ll get started with the pulley assembly for now.

Day One Lesson: check your stuff when you get it, not 7 months later.

I bought this kit back in August, and I’m just now getting around to building it.

Why? I don’t have a great answer - I wanted a 3D printer, stumbled across Voron and RatRig, and, being the kind of person who is an unrepentant lover of maximalism, complexity, and learning from first principles, fell in love with the idea of building one of these things. I ended up going with Voron because at the time, I couldn’t find as complete a kit for RatRig, and the community seemed smaller.

The type of clueless noob I am: very little prior electronics knowledge, zero 3D printing experience or knowledge. However, I still want to make things as complicated as possible, so have spent an inordinate amount of time since August researching mods, CAN, TAP, Beacon, etc. I’ve finally convinced myself to follow the wisdom of others in building basically stock to start. That said:

Mods:

- clicky clack door

- Orbiter 2 runout sensor

- Knowmi (cuz it seems fun)

-Nitehawk

On the fence about, but it’s not too late:

- TAP vs Beacon

- inverted electronics

Note to self: NO (for now).

Anyway, I just started putting the frame together. @jonhi has a wonderful build log here that reminded me that LDO has its own build notes for its kits, so I took a look and found the very first note about installing the T-nuts first. Of course.

Actually, the T-nuts went into the completed frame just fine, thankfully .

However, now I’m at a hard stop because I just realized…..I bought printed parts for the wrong damn printer!!! After endless rooting around for the z-axis assembly and cussing out the hapless PIF-er, I finally looked at my actual order and the parts are for a V0.2. Did I mention clueless anywhere?

I’ll get started with the pulley assembly for now.

Day One Lesson: check your stuff when you get it, not 7 months later.

Last edited: