Okay, where did I leave off?

Oh yes, a couple more CN mistakes:

I went to put the xy drives together, and had various issues with the screws not fastening. I spent 8 hrs reprinting the parts on the Creality. Well. Turns out that

a) I somehow completely missed the part in the manual about putting nuts into the back of the printed part and

b) I installed the bearings and pulley in the wrong places.

This isn’t the first time I’ve installed something backwards; I’m really starting to question my spatial reasoning (and/or ability to read the manual)!

And whew - I wasn’t feeling 100% confident in my ABS printing with the Creality for such critical parts, although I used the recommended settings for the parts and they looked good.

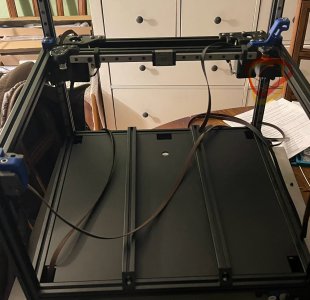

The gantry is mostly assembled, although I **cannot** get one screw into the z block. (The one you insert from the bottom into the xy drives when the gantry’s suspended.). The LDO manual recommends doing this while you have it upside down on your workspace, but I couldn’t get it in (I suspect the nut was falling down in its socket a bit, just out of reach of the screw.)

So I flip it over, rest it on the rails, and 3 screws go in like butter. One has resisted all attempts. I took the gantry down, flipped it back over, undid the belt clamp, to make sure I’d actually put a nut in the dang socket (ahem). I had! I tested the screw in the nut while I had it down; not a bad screw or nut. I did find that I’d forgotten to tighten the drives and blocks, so I guess something good came of all this messing around.

Put it back up, and nope - still won’t tighten. I’ve tried exerting gentle downward pressure from above, making sure the screw’s in the right socket, driving the screw in the other direction (at least one other screw is lefty-tighty); nothing.

So, I’ll give it another go tomorrow unless someone’s got thoughts. It’s very possible I’m missing something dumb.

(Red shape for location of offending screw.)