the bed is heavy and with wiring left and you needing to flip the printer and move it here and there having that heavy bed will make things cumbersome. also put some stops on linear rails as you dont want them sliding back and forth as you still complete the rest of your build. once you finish most of your electronics then finally you can put the bed.Shoes:

View attachment 4407

(I’ll try to up my photo game after this post.)

YACN moment: belatedly realizing that brown paper on the sides of the deck had to be removed.

While trying to figure that out, I randomly came across this post about deck supports, which are mentioned in the LDO notes as something to install around page 29 of the Voron manual. These supports are never mentioned again in either the LDO notes or the Voron manual (that I can find), although the STLs exist on both Githubs. Of course I do not have either version in my pile of printed parts (or in my V0.2 parts).

How important are they for an acrylic deck? (They seem to be, if I don’t want to have to replace a warped deck in 0-300 hours of print time.)

Options:

- try printing them on my Creality in something other than ABS.

- get an aluminum or poly deck

- say the hell with it and move on.

Appreciate any input on that.

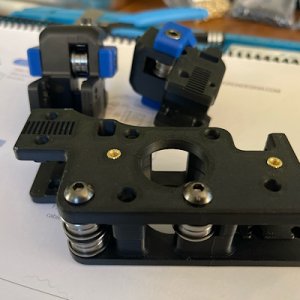

In the meantime, I put the z idlers together and installed:

View attachment 4408

In other notes, I replaced the rail with the loose carriage/bearings with one of the others and ordered a new one from Fabreeko. Maybe one day I’ll try again with repacking the bearings, but I gotta move on with my life at this point.

One last question: I’ve seen a lots of build logs where the builder leaves off installing the bed til later. This is the next step in the Voron manual. Should I wait, or do it now?

I’m gonna start building the a/b drives and idlers in the meantime.

i will be doing the same. i just did one test for my trident while i assemble it is check if my trident three z-axis motors dont sag with bed + heater + magnetic sheet + print surface + some more weight as it has a moving bed. I dont want that once the printer is powered off and bed is mid air it all comes crashing down. so once this test was done i removed the bed.