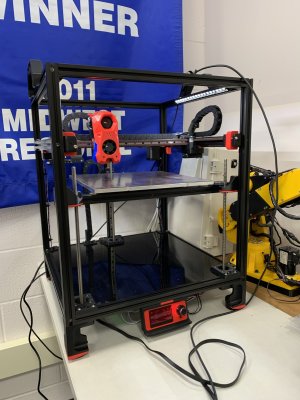

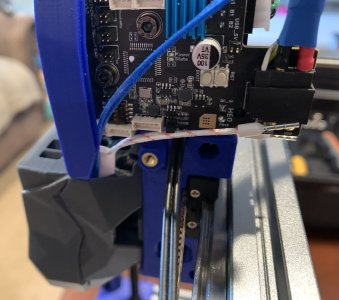

So, why am I taking my time finishing this up? Well, I killed a CAN board that I had squirreled away for this build. It was a beta version of the Mellow boards that had a flaw in a switch mounting. TL/DR, too much stress ripped a pad off of the PCB, and my micro-soldering skills need some work. I may still be able to save it, but at some point i have to admit that my time is worth something, and I can’t keep chasing that repair unless it’s just for fun.

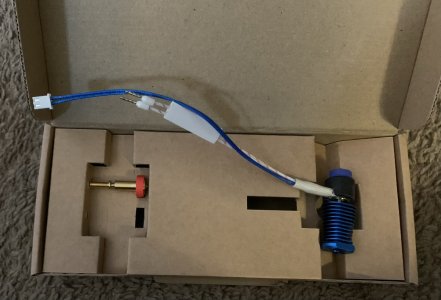

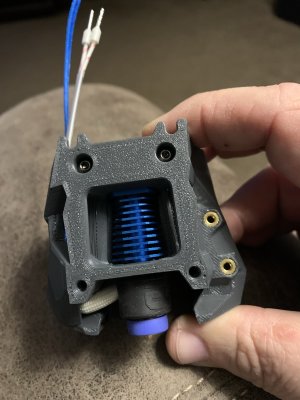

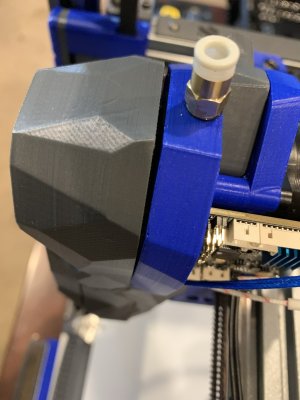

I understand that the flaw has since been fixed. So, I’m waiting on a new board to come in. I’m also hoping to stall for long enough that I can snag one of the new blue anodized Revo Voron Edition hot ends that LDO will be releasing “soon”. I’ve seen pictures, and they look super snazzy.

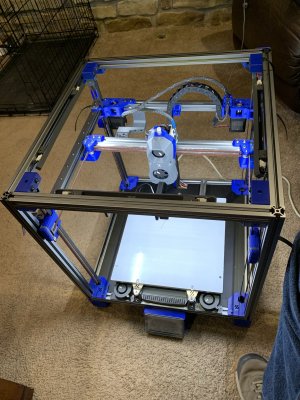

Until then, I’ve just got the bed to mount and a chamber camera to install, and I think that will be it until the CAN board arrives.

I understand that the flaw has since been fixed. So, I’m waiting on a new board to come in. I’m also hoping to stall for long enough that I can snag one of the new blue anodized Revo Voron Edition hot ends that LDO will be releasing “soon”. I’ve seen pictures, and they look super snazzy.

Until then, I’ve just got the bed to mount and a chamber camera to install, and I think that will be it until the CAN board arrives.