VORON Design

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LDO 2.4/300 Build Log

- Thread starter Dave

- Start date

Laserbea4k43

Well-known member

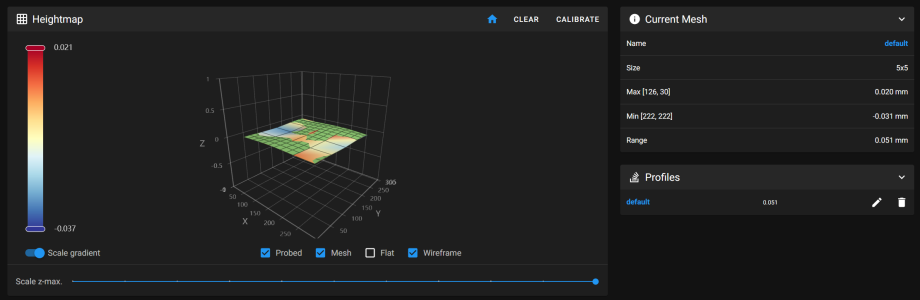

I have NEVER seen green on a bed mesh. what in the world?

The green is a visualization of the calculated mesh that is is applied to the g-code to account for the bed shape. The overlay is just a visual representation of how well the mesh matches the probed bed height. You, too, can get the green if you check appropriate check boxes!I have NEVER seen green on a bed mesh. what in the world?

Got a test print running this morning before work so that I could drop in a Cereal request and try to snag SN5000. A little birdie told me that the chances of that were slim to none that I would get 5000 since someone else has been camping on it for a while. Hmmm. . . . I wonder who will end up with SN5000. . . . .

Laserbea4k43

Well-known member

Easier to get backers on the rails with CAN bus. I see...

Easier to get backers on rails while building from scratch rather than while retrofitting! But I’ve found that not using X/Y cable chains is good and bad. The umbilical is easier to work on, but it’s also a bit tricky in terms of interfering with other stuff in the printer. I’m not sure which I prefer, but it’s nice to have options.Easier to get backers on the rails with CAN bus. I see...

LoadMaster7

Well-known member

Dave, what are you finding that interferes between the umbilical? I am going to be switching to CAN in the near future and am interested in the problems I may have along the way. Thanks.Easier to get backers on rails while building from scratch rather than while retrofitting! But I’ve found that not using X/Y cable chains is good and bad. The umbilical is easier to work on, but it’s also a bit tricky in terms of interfering with other stuff in the printer. I’m not sure which I prefer, but it’s nice to have options.

Its pretty minor, but the can cables can wrap around rhe z cable chain. The fix is piano wire to give the wires some rigidity, but that’s not a big deal.Dave, what are you finding that interferes between the umbilical? I am going to be switching to CAN in the near future and am interested in the problems I may have along the way. Thanks.

brendanm720

Well-known member

Interesting. I never would have thought of that. I was thinking about putting some abs filament in the sleeve with the cable, but the piano wire sounds like maybe it would be more durable. Does the steel wire act like an antenna and interfere with the canbus at all?Its pretty minor, but the can cables can wrap around rhe z cable chain. The fix is piano wire to give the wires some rigidity, but that’s not a big deal.

Not that I’ve ever heard of!Interesting. I never would have thought of that. I was thinking about putting some abs filament in the sleeve with the cable, but the piano wire sounds like maybe it would be more durable. Does the steel wire act like an antenna and interfere with the canbus at all?

I did that on my 2.4x350, and I don’t love it. I wish I had a better reason than “I just don’t like it”, but I don’t. But I agree, it works perfectly well!I can tell you what I did was ran the BUS cable out the back where the exhaust filter used to be. Works great.

I like how the cable sits on the inside, but on the outside running down the back is what I don't like, even though I have it sleeved. I might print a small enclosure or panel to make it just a little cleaner.I did that on my 2.4x350, and I don’t love it. I wish I had a better reason than “I just don’t like it”, but I don’t. But I agree, it works perfectly well!

I have a fried bed thermistor. I mounted another thermistor to the plate and am using that for bed temp feedback for now. There seems to be an issue with the wire somewhere, but I’m not sure where. My guess is that it’s right by the rear center mounting hole. The wires are cramped, and wish that the wire bundle wasn’t perfectly centered. It‘s just awkward there. But it looks like the new thermistor will fix it, so no real worries. I’m just reminded of all of the ways that these printers aren’t quite ready for use in production environments. (Red line is that original heater thermistor, and blue is the replacement. The offset is due to the mounting location. The other traces: Purple is hot end, green is chamber, teal is frame, and the lower temp purple line is from the CAN onboard thermistor.)

Sail hatin

Member

Hey there. Great post. Good info. So if I’m not looking for the Lexus experience and I’m not only a lifelong Toyota guy, but an fj62 guy….what kit would you suggest? I don’t like the idea of paying top dollar for an experience I don’t care about but I’m also not looking for a Honda or a Kia. I appreciate your time and have a great night.Before anything else, let’s get organized! The best thing I ever did for helping my printer builds run smoothly was to make a screw bin. I’ve already got one with my stainless hardware, but LDO uses hardware with a black coating, so I don’t want to mix those bins. I’m not entirely sure what the coating is, but it’s NOT black oxide. The hardware is high quality. This is nowhere more obvious than in the brass 5mm spacers. They are much better than the stamped washers that I’ve seen in some kits. As long as they are the right thickness, they will work, but this attention to detail in a “minor” part is indicative of the quality of the kit top to bottom.

This brings up my only real gripe with the LDO kits: I think that they are too expensive. I, personally, would not have splurged on machined brass spacers, for example (but man, are they well made!--see picture). I don’t think that they provide a good return on investment in terms of performance. There are other, similarly overly nice parts throughout the kit that I think are overkill for their job. And to be fair, that's exactly what LDO is trying to do with this kit! They aren’t trying to compete with the cheap kits. They are trying to provide a no-compromises, extremely high quality kit for folks who want the best parts out of the box. They are selling the Lexus experience when others are selling Toyotas. and even though I, personally, am not a Lexus guy, there is no denying that the premium experience comes with a lot of nice perks.

The thing that I DID really appreciate was the metal handles. I always print out handles to help make working on and moving printers easier, but these handles will make that unnecessary. The feel like good quality, and they look great. This is an addition that I can get behind!

A few other things to note: the tools that come with the kit are just about all that you will need to build the printer. You will need scissors and a soldering iron, but I think that’s about it in terms of extra tools. I’ll be using my own tools because nice handles are nice, but it is good that LDO includes a solid tool selection. The heat set insert tool is especially nice if you don’t already have one. A generous roll of VHB tape, appropriately sized zip ties, and some Bowden tubing round out this box. Lots of good stuff.

Similar threads

- Replies

- 24

- Views

- 1K

- Replies

- 67

- Views

- 21K