First questions as I begin the build.

1) The motor/pully spacing tool seems not to have been included in the essential parts kit from matter hackers. Is this by design?

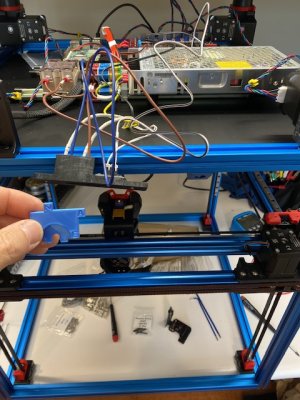

2) I seem to have two sets ( four parts) of x carriage parts. Is this correct? Looks like 2x left and 2x right parts and identical.

Thanks for helping a newbie out!

1) The motor/pully spacing tool seems not to have been included in the essential parts kit from matter hackers. Is this by design?

2) I seem to have two sets ( four parts) of x carriage parts. Is this correct? Looks like 2x left and 2x right parts and identical.

Thanks for helping a newbie out!