I'm old enough to remember when house phones and lamp sockets were made with Bakelite. It's a heavy material but a great insulator and tough stuff!I went to do the bed next and despite doing inventory 3 times, I couldn't find the m4 thumbscrews that are used as spacers.

I did however find:

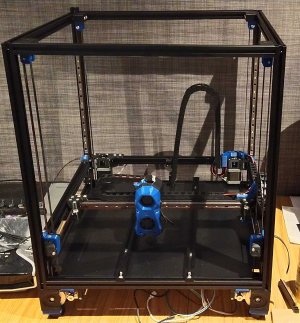

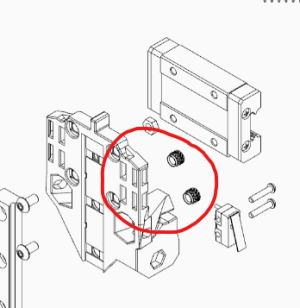

View attachment 3377

I initially thought that they were wood, which worried me.

I contacted Formbot, asking about them, and they assured me that they were indeed replacement parts, and that I could use them as spacers.

Some more research and it turns out that they are made from Bakelite, which is a resin filled with wood fibers (hence the wood like appearance).

However it is known for its lack of electrical conductivity and heat resistant properties, the latter being very important for holding up a heated bed.

VORON Design

Register a free account today to become a member! Once signed in, you'll be able to participate on this site by adding your own topics and posts, as well as connect with other members!

Formbot Voron 2.4r2 "Bruiser" build log

- Thread starter Bionicall

- Start date